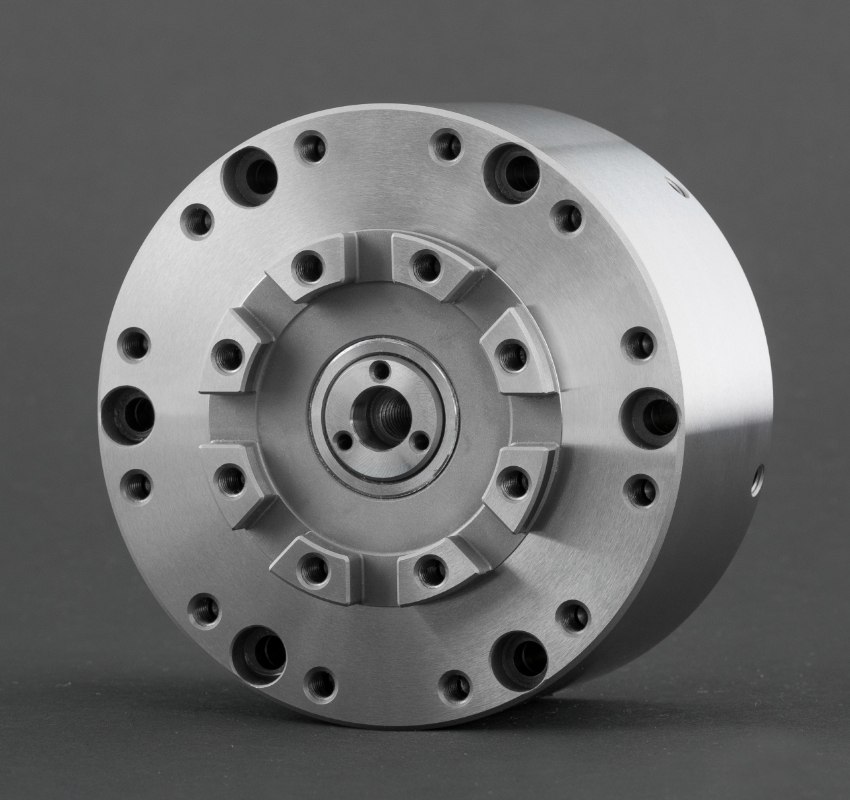

Diaphragm Type High Precision Air Chuck

PIONEER Diaphragm Chuck is to clamp the workpiece as soft as possible, and evenly, to avoid the deformation when clamping by utilizing the tensile strength of special material used for diaphragm. Naturally, the highest possible accuracy is obtainable in turning. Up to 12,000min-1 operation is possible due to the unique design which reduce the affection of centrifugal force. Super high precision and performance in turning is ensured.

- Size:3” to 6”

- Repeatability:Within 0.4μm

- Maintenance Free (No lubrication necessary)

- Std. Rotary Type / Quick Change Type

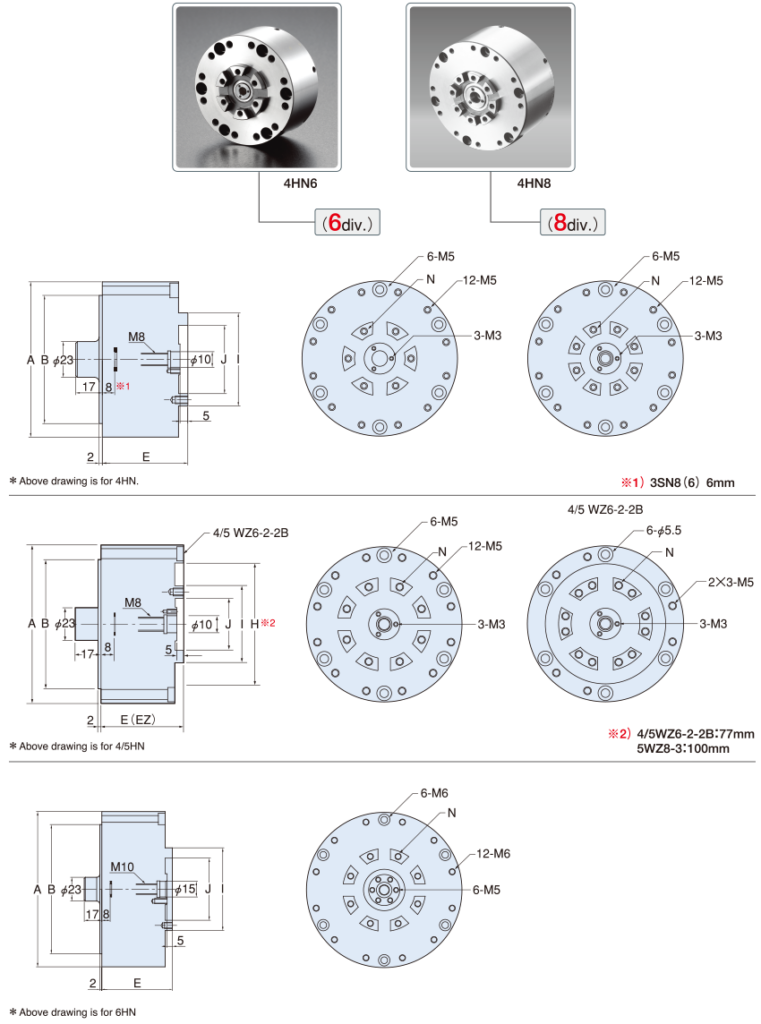

Model No./Dimension/Spec.

Dimensions & Specification

*8 and 6 following HN or WZ means the number of seats where the jaw is mounted on, and naturally the type of jaw to be used with.

| Model No. | A | B | E | I | J | PCD M | PCD N | N | Speed | Chucking cap. | T.I.R. | Wgt.kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3HN6-3 | 82 | 60 | 55 | 36 | 25 | 70 | 30.5 | 6-M4 | 12,000min-1 | 2.0mm~ 40.0mm | ≦0.4μm | 1.7 |

| 3HN8-3 | 82 | 60 | 55 | 36 | 25 | 70 | 30.5 | 8-M4 | 12,000min-1 | 2.0mm~ 40.0mm | ≦0.4μm | 1.7 |

| 4HN6-3 | 100 | 82.55 | 55 | 48 | 32 | 88.9 | 40 | 6-M5 | 12,000min-1 | 2.0mm~ 60.0mm | ≦0.4μm | 2.6 |

| 4HN8-3 | 100 | 82.55 | 55 | 48 | 32 | 88.9 | 40 | 8-M5 | 12,000min-1 | 2.0mm~ 60.0mm | ≦0.4μm | 2.6 |

| 4/5HN8-3 | 100 | 82.55 | 55 | 60 | 44 | 88.9 | 52 | 8-M5 | 10,000min-1 | 2.0mm~ 60.0mm | ≦0.4μm | 2.6 |

| 6HN8-3 | 150 | 124.97 | 68 | 80 | 60 | 135.8 | 70 | 8-M6 | 8,000min-1 | 3.0mm~ 90.0mm | ≦0.4μm | 7.1 |

| 6/8HN8-3 | 150 | 124.97 | 68 | 102 | 77 | 135.8 | 90 | 16-M6 | 8,000min-1 | 3.0mm~ 90.0mm | ≦0.4μm | 7.1 |

| 4/5WZ6- 2-2B | 100 | 82.55 | 53 | 60 | 44 | 88.9 | 52 | 2X6-M5 | 8,000min-1 | 2.0mm~ 60.0mm | ≦0.4μm | 2.3 |

| 5WZ8-3 | 126 | 101.6 | 58 | 60 | 44 | 114.3 | 52 | 8-M5 | 8,000min-1 | 3.0mm~ 70.0mm | ≦0.4μm | 3.8 |

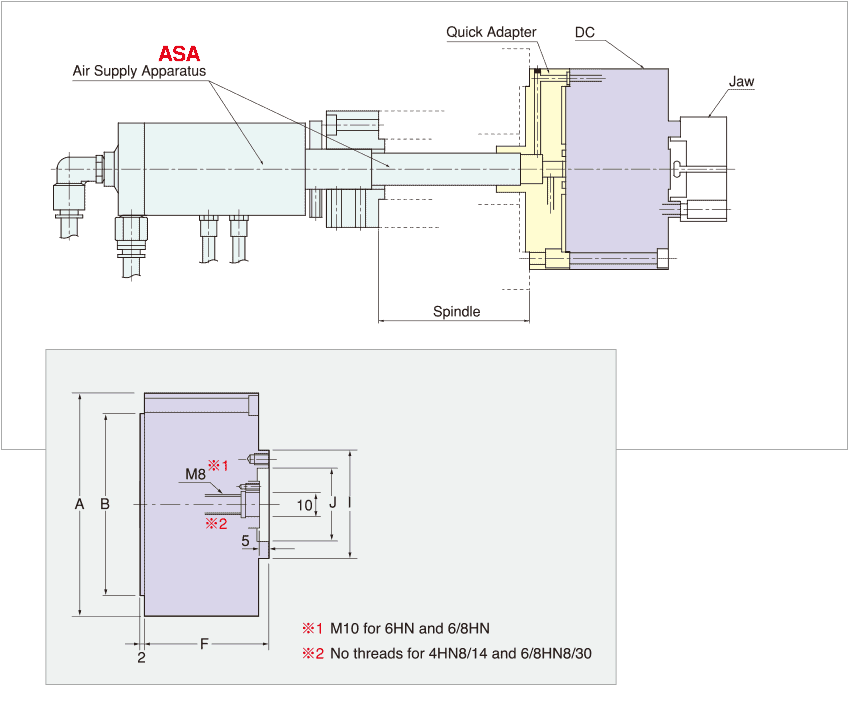

Quick Change System

Chuck can be changed without dismounting the ASA.

Changeover time is drastically reduced, and machine’s down time is also significantly reduced.

Dimensions & Specification

Refer to the equivalent model for the spec. of mounting bolt etc.

| Model No. | Aφ | Bφ | F | Iφ | Jφ | Wgt.kg | |

|---|---|---|---|---|---|---|---|

| ③ | 3HN6-3-QTN | 82 | 60 | 45 | 36 | 25 | 1.4 |

| 3HN8-3-QTN | 82 | 60 | 45 | 36 | 25 | 1.4 | |

| ④ | 4HN6-3-Q | 100 | 82.55 | 55 | 48 | 32 | 2.6 |

| 4HN8-3-Q | 100 | 82.55 | 55 | 48 | 32 | 2.6 | |

| 4/5HN8-3-Q | 100 | 82.55 | 55 | 60 | 44 | 2.6 | |

| 4HN8/14-3-Q | 100 | 82.55 | 55 | 48 | 32 | 2.5 | |

| New Triple Piston | |||||||

| 4HN8-3-QT | 100 | 82.55 | 58 | 52 | 32 | 2.9 | |

| ⑥ | 6HN8-3-Q | 150 | 124.97 | 68 | 80 | 60 | 7.1 |

| 6/8HN8-3-Q | 150 | 124.97 | 68 | 102 | 77 | 7.1 | |

| 6/8HN8/30-3-Q | 150 | 124.97 | 68 | 102 | 77 | 6.8 | |

8 or 6 after Hn signify the number of seats where the jaw is mounted on, i.e., the number of slits of jaw to be used with DC.

Triple piston …… has the equivalent repeatability to double piston type, and 1.4 times in gripping power.

Jaw/Form Machining

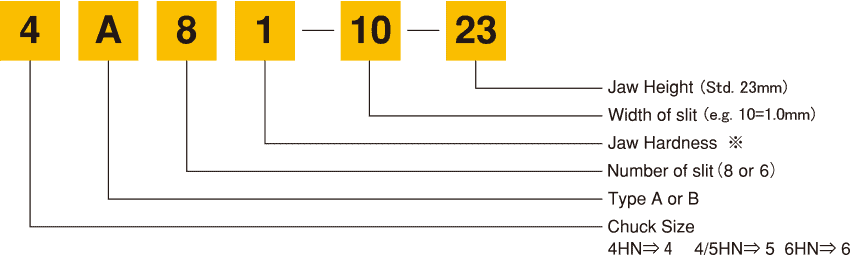

How to order std. blank jaw

※Std. blank jaw is made of die steel pre-hardened to HRC40.

Other material and hardness can be used, but, it is suggested to be consulted for the propriety to the application.

Hardened to HRC55-60 jaw is available.

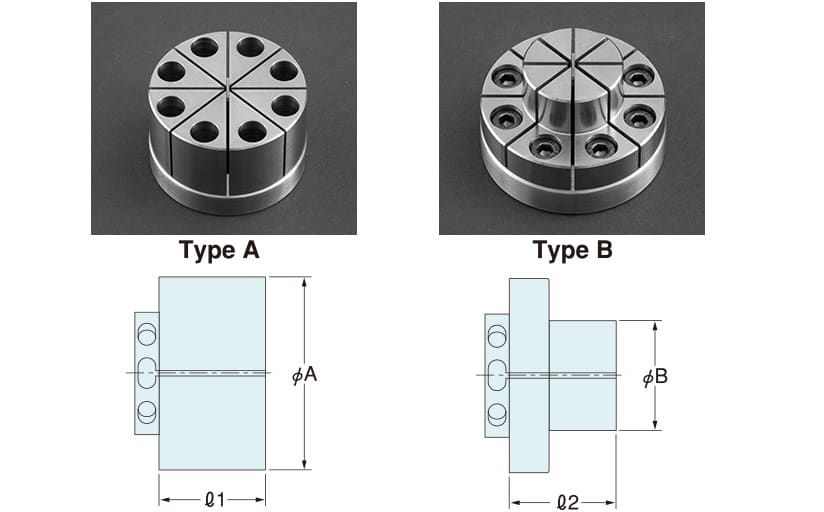

Outline Drawing of Std. Jaws

Dimensions of Std. Jaw

| ChuckJaw | TypeA | TypeB | ||||

|---|---|---|---|---|---|---|

| φA | ℓ1 | φB | ℓ2 | |||

| 3HN | 40 | 23 | 30 | 22 | 23 | 30 |

| 4HN | 52 | 23 | 30 | 28 | 23 | 30 |

| 5WZ 4/5HN | 63 | 25 | 30 | 40 | 25 | 30 |

| 6HN | 82 | 25 | 30 | 50 | 25 | 30 |

| 6/8HN | 110 | 25 | 30 | – | – | – |

Other sizes available on request as option.

Type A is basically for OD clamping, and Type B is for ID clamping.

The selection of A or B depends on how fast and efficiently it can be form-machined to the required shape.

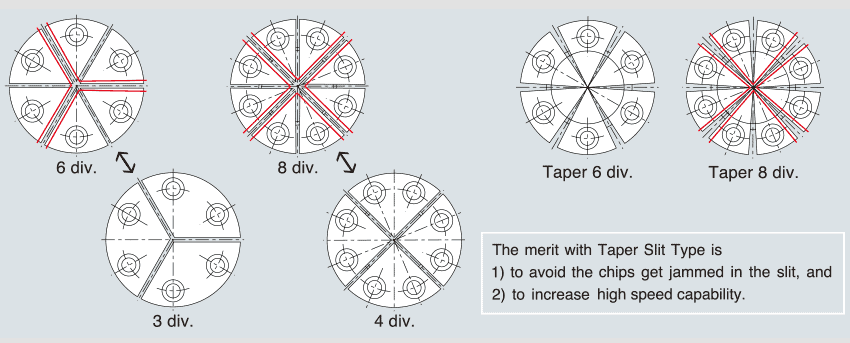

Type of Jaw